Oomatshini be-Extrusion abaqhubekayo

Iingenelo

I-1, i-plastic deformation yentonga yokutya phantsi kwamandla okubetha kunye nobushushu obuphezulu obususa iziphene zangaphakathi kwintonga ngokwayo ngokupheleleyo ukuze kuqinisekiswe iimveliso zokugqibela kunye nokusebenza kakuhle kwemveliso kunye nokuchaneka okuphezulu.

2, hayi preheating okanye annealing, iimveliso ezilungileyo ezifunyenwe ngenkqubo extrusion kunye nokusetyenziswa kwamandla aphantsi.

3, kunye nesayizi enye yokutya intonga, umatshini unokuvelisa uluhlu olubanzi lweemveliso ngokusebenzisa ukufa okuhlukeneyo.

I-4, umgca wonke ulula kwaye uqhutywe ngokukhawuleza ngaphandle komsebenzi onzima okanye ukungcola ngexesha lokukhupha.

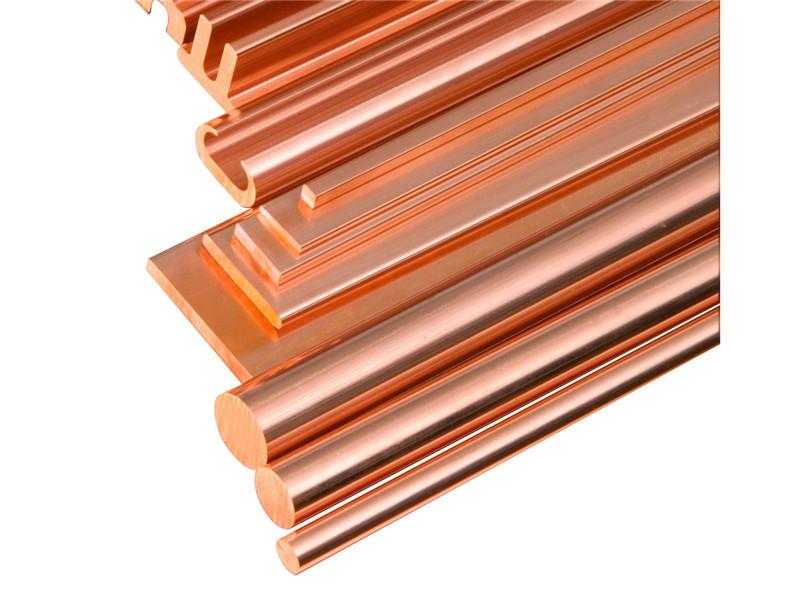

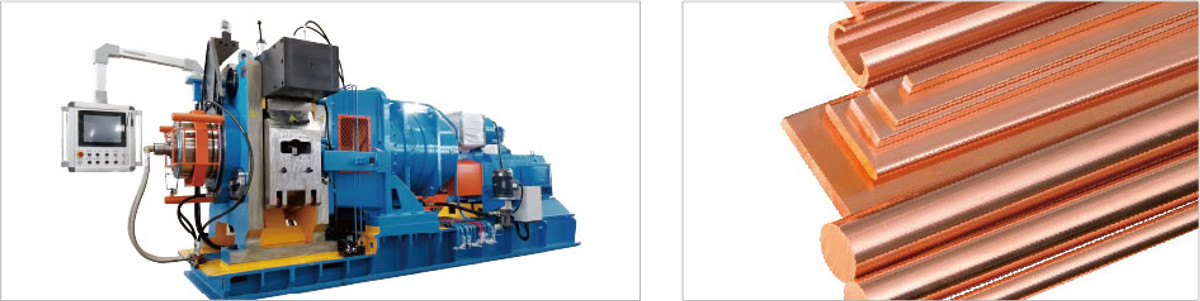

Ukutya ngentonga yobhedu

1.Ukwenza iingcingo zobhedu, i-copper busbar encinci kunye nocingo olujikelezayo

| Umzekelo | I-TLJ 300 | I-TLJ 300H |

| Amandla eMoto angundoqo(kw) | 90 | 110 |

| Ukutya intonga dia. (mm) | 12.5 | 12.5 |

| Max. ububanzi bemveliso (mm) | 40 | 30 |

| I-Flat Wire Cross-Sectional | 5-200 | 5 -150 |

| Imveliso(kg/h) | 480 | 800 |

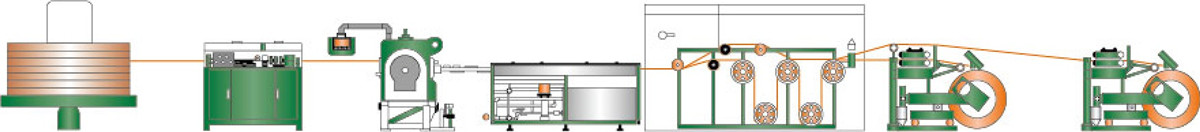

UYilo loMda weMveliso

Intlawulo ye-Pretreatment Pretreatment Extrusion Machine Cooling Sys. Umatshini wokuthatha umdanisi

2.Ukwenza i-copper busbar, ubhedu olujikelezayo kunye neprofayili yobhedu

| Umzekelo | I-TLJ 350 | I-TLJ 350H | I-TLJ 400 | I-TLJ 400H | I-TLJ 500 | TLJ 630 |

| amandla amakhulu emoto(kw) | 160 | 200 | 250 | 315 | 355 | 600 |

| intonga yokutya dia. (mm) | 16 | 16 | 20 | 20 | 25 | 30 |

| max. ububanzi bemveliso (mm) | 100 | 100 | 170 | 170 | 260 | 320 |

| imveliso intonga dia.(mm) | 4.5-50 | 4.5-50 | 8-90 | 8-90 | 12-100 | 12-120 |

| indawo yemveliso enqamlezileyo (mm2) | 15-1000 | 15-1000 | 75-2000 | 75-2000 | 300-3200 | 600-6400 |

| imveliso(kg/h) | 780 | 950 | 1200 | 1500 | 1800 | 2800 |

UYilo loMda weMveliso

I-Fieder-off Feeder & straightener Extrusion Machine Cooling Sys. Ubude Counter Product Bench Thatha-up Machine

3. Ukwenza i-copper busbar, i-copper strip

| Umzekelo | TLJ 500U | TLJ 600U |

| amandla amakhulu emoto(kw) | 355 | 600 |

| intonga yokutya dia. (mm) | 20 | 30 |

| max. ububanzi bemveliso (mm) | 250 | 420 |

| max. ububanzi kumlinganiselo wokutyeba | 76 | 35 |

| ubukhulu bemveliso(mm) | 3-5 | 14-18 |

| imveliso(kg/h) | 1000 | 3500 |

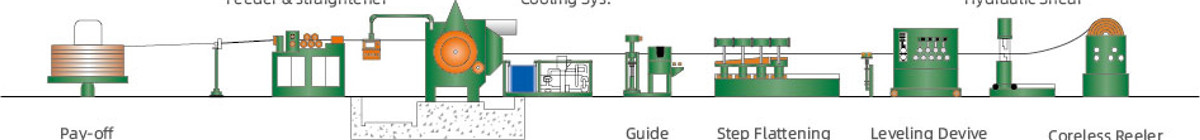

UYilo loMda weMveliso

Ukutya ngentonga yobhedu

Ukufaka isicelo somqhubi we-commutator, ubhedu olungenanto, intonga yobhedu ye-phosphor, intambo yefreyimu ehamba phambili, ucingo loqhagamshelwano lukaloliwe njl.

| I-TLJ 350 | I-TLJ 400 | I-TLJ 500 | TLJ 630 | |

| impahla | 1459/62/63/65 ubhedu cu/Ag (AgsO.08%) | ubhedu lwephosphor (Pso.5%) cu/Ag (AgsO.3%) | ubhedu lwe-magnesium (MgsO.5%) ubhedu lwentsimbi (Feso.l% | ubhedu lwe-magnesium (MgsO.7%)/Cucrzr |

| intonga yokutya dia. (mm) | 12/12.5 | 20 | 20 | 25 |

| max. ububanzi bemveliso (mm) | 30 | I-150 (umcu wobhedu wesilivere) | 100(umcu wesakhelo esikhokelayo:) | 320 |

| imveliso intonga dia.(mm) | i-phosphor copperball: 10-40 | i-magnesium copperrod: 20-40 | i-magnesium copperrod: 20-40 | |

| imveliso(kg/h) | 380 | 800-1000 | 1000-1200 | 1250/850 |

UYilo loMda weMveliso

I-Fieder-off Feeder & straightener Extrusion Machine Cooling Sys. Ubude be-Counter yokuThatha uMshini

Ukutya ngentonga yeAluminiyam

Ukufaka isicelo socingo olusicaba, ibha yebhasi, kunye nomqhubi weprofayili, ityhubhu engqukuva, iMPE, kunye nePFC Tubes

| Umzekelo | ILLJ 300 | LLJ 300H | ILLJ 350 | ILLJ 400 |

| amandla amakhulu emoto(kw) | 110 | 110 | 160 | 250 |

| intonga yokutya dia. (mm) | 9.5 | 9.5 | 2*9.5/15 | 2*12/15 |

| max. Ububanzi bemveliso yocingo olusicaba (mm) | 30 | 30 | 170 | |

| imveliso yocingo olusicaba indawo enqamlezileyo (mm2) | 5-200 | 5-200 | 25-300 | 75-2000 |

| ityhubhu ejikelezayo dia. (mm) | 5-20 | 5-20 | 7-50 | |

| Ububanzi betyhubhu ecaba (mm) | - | ≤40 | ≤70 | |

| ucingo olucaba / ityhubhu Imveliso(kg/h) | 160/160 | 280/240 | 260/260 | (600/900)/- |

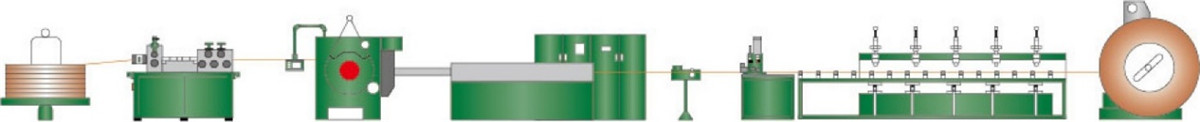

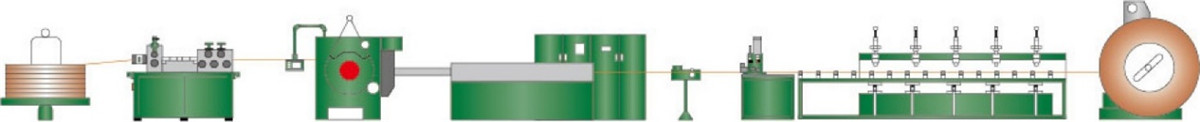

UYilo loMda weMveliso

Intlawulo-off straightener Ukucoca Ultrasonic Ukupholisa Sys Dancer Take-up Machine

Umfanekiso we-217282